Enhancing Smart Factory Efficiency Starts with Caster Wheels: A Guide to Selecting and Applying AGV Casters / AMR Casters

The Future of Smart Factories

Smart factories represent a significant milestone in the manufacturing industry's journey toward digitalization and intelligence. Under this concept, traditional manufacturing systems no longer operate in isolation but are seamlessly connected through the Internet of Things (IoT), integrating machines, personnel, data, and processes into a comprehensive and highly efficient ecosystem. The primary objectives of smart factories include enhancing operational efficiency, reducing costs, improving product quality, and shortening delivery times to adapt swiftly to market changes.

The future of smart factories will be characterized by the following features:

- Full Automation: From material handling to production line operations, robots and automated equipment will gradually replace manual labor, executing repetitive and high-precision tasks to significantly improve efficiency.

- Real-time Data Analytics: Leveraging big data analysis and cloud computing, smart factories can monitor production data in real time, quickly predict equipment anomalies, and perform preventive maintenance, thereby enhancing production stability and operational efficiency.

- Customized Production: Smart factories can rapidly adjust production processes to accommodate market demands, achieving mass customization and meeting the diverse needs of customers.

- Green Manufacturing: With energy conservation, carbon reduction, and environmental protection at the core, smart factories minimize resource wastage and improve energy utilization efficiency, realizing sustainable production models.

In this manufacturing environment, Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) play an indispensable role. They not only enable unmanned material handling but also dynamically adjust transport routes to meet the evolving demands of production. Therefore, the stability, flexibility, and durability of AGVs and AMRs are crucial to the successful operation of smart factories, and these attributes rely on high-quality trailing wheels.

The Role of AGV/AMR Caster in Smart Factories

In smart factory operations, AGVs and AMRs serve as more than just simple logistics tools; they have become key equipment for achieving flexible production line adjustments and efficient transportation. As one of their core components, trailing wheels play a decisive role, directly impacting the stability and efficiency of the equipment.

Why Are Trailing Wheels Crucial?

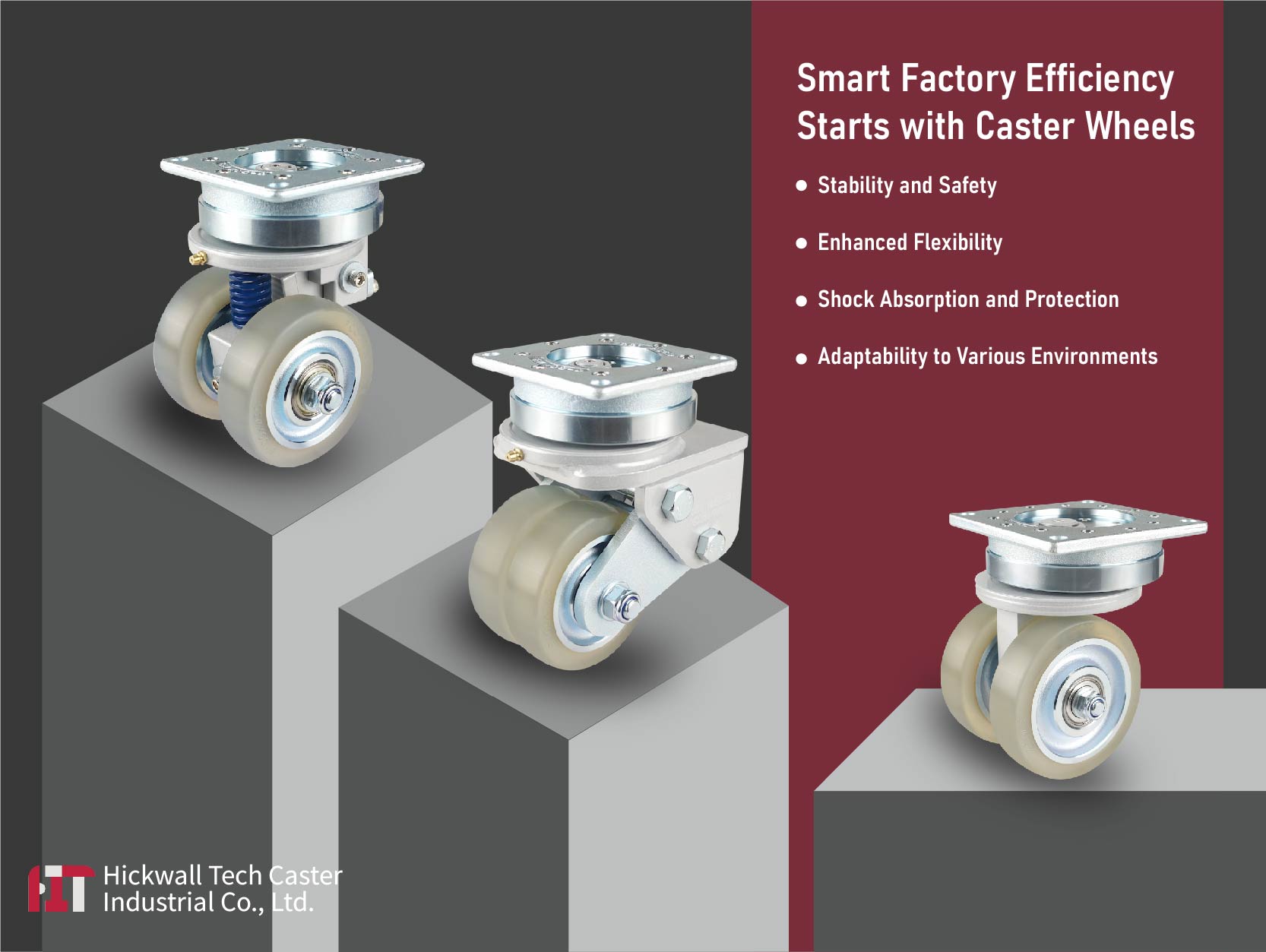

- Stability and Safety

The high load-bearing capacity of trailing wheels ensures the stability of AGVs/AMRs when transporting heavy loads, preventing tilting or overturning and ensuring operational safety. - Enhanced Flexibility

High-quality trailing wheels enable AGVs/AMRs to maneuver efficiently in confined spaces, adapting to complex production environments such as multi-path routes and dynamically arranged factory layouts. - Shock Absorption and Protection

The shock-absorbing properties of trailing wheels effectively mitigate vibrations, preventing damage to flooring or equipment. This is particularly crucial when transporting sensitive items such as electronic components or precision instruments. - Adaptability to Various Environments

Different areas within a smart factory (e.g., warehouses, electronic manufacturing workshops, or medical logistics centers) have varying requirements for trailing wheels, such as noise reduction, anti-static properties, and high wear resistance.

Core Value for Smart Factories

- Efficient Transportation: Trailing wheel designs ensure smooth AGV/AMR operation, minimizing efficiency losses caused by vibrations.

- Reduced Maintenance Needs: The use of highly durable materials and designs lowers equipment downtime and maintenance costs, extending overall equipment lifespan.

- Support for Intelligent Management: By integrating data analytics and smart control, the operating status of AGV/AMR caster can be monitored in real time, further enhancing factory automation levels.

Hickwall's Recommended GAMT, GAMS, and GAMA Series for Smart Factories

- Heavy Duty AGV/AMR Caster GAMT Series

The GAMT series features a dual-rotational structure and high load-bearing capacity, specifically designed for heavy-duty material transportation and high-frequency applications. Its stable structure ensures smooth operation under heavy loads, making it ideal for automated production lines and large warehouse environments.

- Application Scenarios: Frequent heavy-load automated production lines, large-scale warehouse logistics systems.

- Product Advantages: High load capacity and flexible maneuverability, suitable for complex environments.

- Heavy Duty AGV/AMR Caster GAMS Series

The GAMS series focuses on shock absorption, employing a specialized structural design to effectively reduce vibrations during operation, protecting both equipment and transported items. This series is particularly outstanding in high-precision applications such as electronics manufacturing and medical logistics.

- Application Scenarios: Electronics manufacturing plants, medical logistics.

- Product Advantages: Excellent shock absorption performance, ensuring the safety of equipment and transported goods.

- Heavy Duty AGV/AMR Caster GAMA Series

The GAMA series integrates dual-rotational casters, a tilting structure, and spring-based shock absorption, combining stability with noise reduction. It is particularly suited for precision transportation and low-noise applications, such as intelligent warehousing and high-end medical logistics.

- Application Scenarios: Intelligent warehousing, precision manufacturing, medical logistics.

- Product Advantages: Stable shock absorption and noise-reducing design, adaptable to diverse needs.

Application Scenarios in Smart Factories

- Intelligent Warehousing and Logistics

AGVs and AMRs play a crucial role in intelligent warehousing systems, ensuring rapid material transportation. The stability and flexibility of trailing wheels are essential in high-frequency sorting and distribution processes. - Electronics Manufacturing Plants

Electronic components are highly sensitive to static electricity. Hickwall’s anti-static trailing wheels effectively prevent electrostatic damage, ensuring safety during production. - Medical Logistics

The transportation of medical equipment and pharmaceuticals requires high stability and low noise. The GAMA series’ silent and shock-absorbing features offer the best solution for medical applications. - Automated Production Lines

In factories that frequently adjust production layouts, the GAMT series’ high load-bearing capacity and flexibility enable quick adaptation, significantly improving production efficiency. - High-vibration Environments

In industrial settings with significant vibrations, the GAMS series’ shock absorption capabilities drastically reduce equipment wear, ensuring stable operation.

Conclusion

The success of smart factory operations depends on high-quality equipment, and Hickwall’s GAMT, GAMS, and GAMA series trailing wheels are the ideal choice for AGVs/AMRs. These wheels not only offer exceptional load-bearing capacity, shock absorption, and flexibility but also can be customized for various industrial scenarios, ensuring efficient operations in smart factories.

If you are looking for high-performance trailing wheels for smart factories, contact us now to learn more about our products and applications. Let Hickwall be your best partner in automation transformation!